Ultrasonication

| Technology | |

| |

| Technology details | |

| Name: | Ultrasonication |

| Category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| Feedstock: | Biowaste |

| Product: | Biomass (dispersed, disrupted, emulsified, extracted, homogenised) |

Ultrasonication is a physical treatment to disperse, disrupt, emulsify, extract, and/or homogenise biomass via the application of ultrasonic frequencies (>20 kHz). The propagation of sound waves through the biomass results in spontaneous formation and collapse of microsized cavities. This activity produces a hot-spot effect, resulting in high temperature and pressure gradients to form locally, while the overall conditions remain ambient. This effect can be used to break down morphologies, for example for the depolymerisation of lignocellulosic biowaste.[1]

Feedstock

Composition

The requirements on the composition of the feedstock may vary since ultrasonication can be utilised at various points in the value chain of biowaste valorisation.

Pre-treatment

Ultrasonication is often the first step of the pretreatment, although initial sizing may be required.

Process and technologies

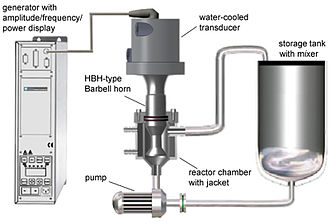

During the ultrasonication treatment, ultrasound is transmitted through any physical medium by waves that compress and stretch the molecular spacing of the medium through which it passes[2]. The distance between the molecules will vary as they oscillate about their mean position[2]. When the negative pressure is large enough, the distance between the molecules of the liquid exceeds the minimum molecular distance required to hold the liquid intact, and then the liquid breaks down and voids (cavitation bubbles) are created[2].

The medium for ultrasonication can be water, an organic solvent, or a dilute acid or base.[1]

Product

Ultrasonication can be used to produce:

- Emulsions (such as nanoparticles, nanoemulsions, nanocrystals, liposomes, wax emulsions)

- Extracts from biomass (such as polysaccharides[3], oil, anthocyanins and antioxidants[4])

- Purified wastewater

Furthermore, ultrasonication is also utilised in following processes:

- Adhesive thinning

- Cells disruption

- Degassing liquids

- Polymer and epoxy processing

- Ultrasound assisted oxidative desulfurisation of crude oil[5]

Post-treatment

A common application for ultrasonication is breaking down the lignocellulosic structure. The available sugars can then be converted to products such as biofuels, for example by fermentation.[1]

Technology providers

| Company name | Country | Technology category | Technology name | TRL | Capacity [kg/h] | Frequency [kHz] | Power [W] | Processable volume [L] | Feedstock: Food waste | Feedstock: Garden & park waste |

|---|---|---|---|---|---|---|---|---|---|---|

| Everywave Srl | Italy | - | FLOW:WAVE® Tubular reactor | 5 | 2000 | 20-40 | 2000-4000 | 4 | X | X |

| Hielscher Ultrasonics GmbH | Germany | - | UIP16000 | 9 | - | 18 | 40000 | 5 | X | ● |

| Doosan Enpure Limited | United Kingdom | - | SonixTM | - | - | 20 | - | - | X | X |

| Ultrawaves | Germany | - | BIOSONATOR | - | 1980 | 20-1000 | 10000 | 20-50 | X | X |

| VTA | ||||||||||

| Weber | Germany | - | DesiUS/BIOPUSH | 9 | - | 22 | 2000 | - | X | X |

Everywave Srl

| General information | |||

| Company: | Everywave Srl |

| |

| Country: | Italy | ||

| Contact: | info@everywave.eu | ||

| Webpage: | https://www.everywave.eu/en/ | ||

| Technology and process details | |||

| Technology name: | FLOW:WAVE® Tubular reactor | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | 5 | Capacity: | 2 tons/hour per single module kg·h-1 |

| Frequency: | 20/40 kHz | Power: | 2000/4000 W |

| Processable volume: | 4 L | Other: | Continuous process |

| Feedstock and product details | |||

| Feedstock: | By-products and biomasses (slurry, manure, sorghum, triticale, corn silage, other livestock waste, or residues from the agri-food industry, etc.) | Product: | emulsion, mixing, disintegration, sonochemistry, plant extraction, and bactericidal action. |

Everywave Srl is a spin-off from UNITECH Srl that specializes in the research, development and production of solutions in the ultrasound technologies. The continuous and rapid technological evolution and the need for ever higher quality standards require the daily research and development of increasingly innovative solutions where quality and reliability play an absolutely vital role in all working processes. Everywave’s mission has always been to find ideas and improvement solutions in the field of ultrasound technologies, with continuous support to its customers in order to optimize their productivity and therefore their competitiveness.

Today, with a specialized biomass treatment plant, the company also produces biogas from the same by-products: a source that reduces the energy supply costs necessary for the company and generates a new source of income. We have designed and produced a special ultrasonic reactor which, integrated with specialized systems for shredding, pumping and process control, represents a solid and efficient technology for controlling and increasing the production yield of biogas.

Hielscher Ultrasonics GmbH

| General information | |||

| Company: | Hielscher Ultrasonics GmbH |

| |

| Country: | Germany | ||

| Contact: | info@hielscher.com | ||

| Webpage: | www.hielscher.com | ||

| Technology and process details | |||

| Technology name: | UIP16000 | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | 9 | Capacity: | kg·h-1 |

| Frequency: | 18 kHz | Power: | 40,000 W |

| Processable volume: | 5 L | Other: | Biodiesel transesterification (12-50m³/h ) Emulsification (e.g. oil/water 6-32m³/h), Cell extraction (e.g. algae 1-12m³/h), Dispersion/deagglomeration (0.3-6m³/h), Wet milling (0.2-4m³/h) |

| Feedstock and product details | |||

| Feedstock: | Biomass, 2-phase systems | Product: | Dispersion, Emulsion, Cell extract |

Hielscher Ultrasonics specialises in the design and manufacturing of high power ultrasonic homogenisers for lab, bench-top and production level. Ultrasonic power is an effective and energy-efficient means to apply high shear and intense stress to liquids, powder/liquid mixtures and slurries. This makes it a strong alternative to high shear mixers, high pressure homogenisers and agitated bead mills. Hielscher ultrasonic devices are in use worldwide as laboratory mixers, high shear mixing equipment, full-size in-line homogenisers or particle mills. The applications include mixing, dispersing, particle size reduction, extraction and chemical reactions. Hielscher supply to various industry segments, such as nano-materials, paints & pigments, food & beverage, cosmetics, chemicals and fuels.

Doosan Enpure Limited

| General information | |||

| Company: | Doosan Enpure Limited |

| |

| Country: | United Kingdom | ||

| Contact: | |||

| Webpage: | https://www.doosanenpure.com/ | ||

| Technology and process details | |||

| Technology name: | SonixTM | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | Capacity: | 200 m3/d kg·h-1 | |

| Frequency: | 20 kHz | Power: | W |

| Processable volume: | L | Other: | |

| Feedstock and product details | |||

| Feedstock: | Wastewater sludge, or any other biological or cellular material | Product: | Disintegrated material |

Doosan Enpure Limited is a process engineering company specializing in water, wastewater and sludge treatment as well as waste-to-energy solutions with a global presence. We are a wholly-owned subsidiary of Doosan Heavy Industries & Construction, a global conglomerate in the power and water infrastructure sector, headquartered in South Korea.

Doosan Enpure provides a wide range of sludge treatment processes to meet all legislative requirements as well as maximising the recovery of energy and other useful components of the sludge.

Ultrawaves

| General information | |||

| Company: | ULTRAWAVES - Water- and Environmental Technologies GmbH |

| |

| Country: | Germany | ||

| Contact: | |||

| Webpage: | https://ultrawaves.de/en/ | ||

| Technology and process details | |||

| Technology name: | BIOSONATOR | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | Capacity: | 10 to 33 L/min or 0.6 to 2 m3/h biomass suspension kg·h-1 | |

| Frequency: | 20-1000 kHz | Power: | 3000-10000 W |

| Processable volume: | 20-50 L | Other: | |

| Feedstock and product details | |||

| Feedstock: | Renewable raw materials, maize, green waste, slurry, municipal and industrial wastewater | Product: | Disintegrated biomass for further processing |

ULTRAWAVES GmbH develops and markets innovative high-power ultrasonic systems for water and environmental engineering. Apart from the disintegration of biomass in wastewater treatment and biogas plants, the systems are also used in industrial applications. In 2001 Ultrawaves GmbH was founded as spin-off company from TUH. Our patented high-power ultrasound systems were and are developed on the basis of the wealth of knowledge acquired over many years. Ultrawaves is now the worldwide market leader for ultrasound applications in environmental engineering.

The BIOSONATOR is our new complete system consisting of a modular high-power ultrasound system, upstream a macerator and an eccentric screw pump as well as an intelligent control and automation technology with remote maintenance. As a plug and play system, the BIOSONATOR can be quickly and easily integrated into existing biogas plants.

VTA

| General information | |||

| Company: | VTA Technologie GmbH |

| |

| Country: | Austria | ||

| Contact: | |||

| Webpage: | https://vta.cc/en | ||

| Technology and process details | |||

| Technology name: | VTA GSD | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | Capacity: | kg·h-1 | |

| Frequency: | 25 kHz | Power: | 3000-4000 W |

| Processable volume: | 300-2500 L | Other: | |

| Feedstock and product details | |||

| Feedstock: | Sewage sludge | Product: | Dewatered sludge for efficient drying |

VTA is an Austrian group which is successful all over the world. We develop and create innovative system products and technologies which set standards in the waste water and environmental engineering sector. These high-performance, cost-efficient and sustainable solutions are inspired by nature and its cycles.

Optimum sewage sludge treatment, stable digestion operation and reduction of costs – this is what reverse flow disintegration (GSD) with ultrasound, a patented process from VTA Technologie GmbH, has to offer. In VTA GSD, ultrasonic transducers digest the thickened sludge flowing through the disintegration reactor.

Weber

| General information | |||

| Company: | Weber Ultrasonics / ENTEC |

| |

| Country: | Germany | ||

| Contact: | |||

| Webpage: | https://www.weber-entec.com/en | ||

| Technology and process details | |||

| Technology name: | DesiUS/BIOPUSH | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | 9 | Capacity: | kg·h-1 |

| Frequency: | 22 kHz | Power: | 2000 W per unit W |

| Processable volume: | L | Other: | |

| Feedstock and product details | |||

| Feedstock: | Waste water, slurry, maize, silage, grass, manure/GPS | Product: | Disintegrated biomass for further processing |

Weber Entec GmbH & Co. KG is a subsidiary of Weber Ultrasonics AG, one of the world’s leading manufacturers of ultrasound components and ultrasonic welding equipment. Weber Entec concentrates on systems engineering and applications using ultrasound in the field of environmental engineering, especially ultrasonic treatment of biogenic materials, known as disintegration. Weber Entec specializes in disintegration with ultrasound for wastewater treatment and biogas plants.

Because of its broad range of services, the company is a one-stop source for manufacturing, plant construction, sales, system analysis and process optimisation. Developed in a research project with the renowned Fraunhofer Institute, our subsidiary’s systems technology accelerates the decomposition of organic material. Today the Weber Entec technology is at work in biogas and water treatment plants all over the world. Customers benefit from efficient processes and a higher energy yield.

Open access pilot and demo facility providers

Currently no providers have been identified.

Patents

Currently no patents have been identified.

References

- ↑ a b c Preeti Bhagwan Subhedar, 2016: Use of Ultrasound for Pretreatment of Biomass and Subsequent Hydrolysis and Fermentation. Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. (Ed.). Elsevier, Amsterdam, Netherlands.

- ↑ a b c Hugo Miguel Santos, Carlos Lodeiro, and José-Luis Capelo-Martínez, 2008: The Power of Ultrasound. Ultrasound in Chemistry: Analytical Applications. José-Luis Capelo-Martínez (Ed.). Wiley‐VCH Verlag GmbH & Co. KGaA, Weinheim, Germany.

- ↑ , 2017-09-01: Polysaccharides from macroalgae: Recent advances, innovative technologies and challenges in extraction and purification. Food Research International, Vol. 99, 1011–1020. doi: https://doi.org/10.1016/j.foodres.2016.11.016

- ↑ , 2013-09-01: Effect of ultrasound frequency on antioxidant activity, total phenolic and anthocyanin content of red raspberry puree. Ultrasonics Sonochemistry, Vol. 20, (5), 1316–1323. doi: https://doi.org/10.1016/j.ultsonch.2013.01.020

- ↑ , 2020-05-01: Study on ultrasound-assisted oxidative desulfurization for crude oil. Ultrasonics Sonochemistry, Vol. 63, 104946. doi: https://doi.org/10.1016/j.ultsonch.2019.104946