Ultrasonication

| Technology | |

| |

| Technology details | |

| Name: | Ultrasonication |

| Category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| Feedstock: | Biowaste |

| Product: | Biomass (dispersed, disrupted, emulsified, extracted, homogenised) |

Ultrasonication is a physical treatment to disperse, disrupt, emulsify, extract, and/or homogenise biomass via the application of ultrasonic frequencies (>20 kHz). The propagation of sound waves through the biomass results in spontaneous formation and collapse of microsized cavities. This activity produces a hot-spot effect, resulting in high temperature and pressure gradients to form locally, while the overall conditions remain ambient. This effect can be used to break down morphologies, for example for the depolymerisation of lignocellulosic biowaste.[1]

Feedstock

Composition

The requirements on the composition of the feedstock may vary since ultrasonication can be utilised at various points in the value chain of biowaste valorisation.

Pre-treatment

Ultrasonication is often the first step of the pretreatment, although initial sizing may be required.

Process and technologies

During the ultrasonication treatment, ultrasound is transmitted through any physical medium by waves that compress and stretch the molecular spacing of the medium through which it passes[2]. The distance between the molecules will vary as they oscillate about their mean position[2]. When the negative pressure is large enough, the distance between the molecules of the liquid exceeds the minimum molecular distance required to hold the liquid intact, and then the liquid breaks down and voids (cavitation bubbles) are created[2].

The medium for ultrasonication can be water, an organic solvent, or a dilute acid or base.[1]

Product

Ultrasonication can be used to produce:

- Emulsions (such as nanoparticles, nanoemulsions, nanocrystals, liposomes, wax emulsions)

- Extracts from biomass (such as polysaccharides[3], oil, anthocyanins and antioxidants[4])

- Purified wastewater

Furthermore, ultrasonication is also utilised in following processes:

- Adhesive thinning

- Cells disruption

- Degassing liquids

- Polymer and epoxy processing

- Ultrasound assisted oxidative desulfurisation of crude oil[5]

Post-treatment

A common application for ultrasonication is breaking down the lignocellulosic structure. The available sugars can then be converted to products such as biofuels, for example by fermentation.[1]

Technology providers

| Company name | Country | Technology category | Technology name | TRL | Capacity [kg/h] | Frequency [kHz] | Power [W] | Processable volume [L] | Feedstock: Food waste | Feedstock: Garden & park waste |

|---|---|---|---|---|---|---|---|---|---|---|

| Company 1 | [Country HQ location] | [Technology category (if different sub-categories are defined this has to be specified here, the available categories can be found on each technology page under the chapter Process and technologies)] | [Technology name (the "branded name" or the usual naming from company side)] | [4-9] | [numeric value] | |||||

| Company 2 | [Country HQ location] | [(if different sub-categories are defined this has to be specified here, the available categories can be found on each technology page under the chapter Process and technologies)] | [Technology name (the "branded name" or the usual naming from company side)] | [4-9] | [numeric value] | ● |

Hielscher Ultrasonics GmbH

| General information | |||

| Company: | Hielscher Ultrasonics GmbH |

| |

| Country: | Germany | ||

| Contact: | info@hielscher.com | ||

| Webpage: | www.hielscher.com | ||

| Technology and process details | |||

| Technology name: | UIP16000 | Technology category: | Pre-processing (Physical processes and technologies), Post-processing (Physical processes and technologies) |

| TRL: | 9 | Capacity: | kg·h-1 |

| Frequency: | 18 kHz | Power: | 40,000 W |

| Processable volume: | 5 L | Other: | Biodiesel transesterification (12-50m³/h ) Emulsification (e.g. oil/water 6-32m³/h), Cell extraction (e.g. algae 1-12m³/h), Dispersion/deagglomeration (0.3-6m³/h), Wet milling (0.2-4m³/h) |

| Feedstock and product details | |||

| Feedstock: | Biomass, 2-phase systems | Product: | Dispersion, Emulsion, Cell extract |

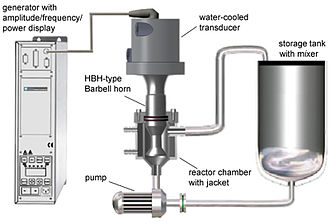

Hielscher Ultrasonics specialises in the design and manufacturing of high power ultrasonic homogenisers for lab, bench-top and production level. Ultrasonic power is an effective and energy-efficient means to apply high shear and intense stress to liquids, powder/liquid mixtures and slurries. This makes it a strong alternative to high shear mixers, high pressure homogenisers and agitated bead mills. Hielscher ultrasonic devices are in use worldwide as laboratory mixers, high shear mixing equipment, full-size in-line homogenisers or particle mills. The applications include mixing, dispersing, particle size reduction, extraction and chemical reactions. Hielscher supply to various industry segments, such as nano-materials, paints & pigments, food & beverage, cosmetics, chemicals and fuels.

Open access pilot and demo facility providers

Currently no providers have been identified.

Patents

Currently no patents have been identified.

References

- ↑ a b c Preeti Bhagwan Subhedar, 2016: Use of Ultrasound for Pretreatment of Biomass and Subsequent Hydrolysis and Fermentation. Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. (Ed.). Elsevier, Amsterdam, Netherlands.

- ↑ a b c Hugo Miguel Santos, Carlos Lodeiro, and José-Luis Capelo-Martínez, 2008: The Power of Ultrasound. Ultrasound in Chemistry: Analytical Applications. José-Luis Capelo-Martínez (Ed.). Wiley‐VCH Verlag GmbH & Co. KGaA, Weinheim, Germany.

- ↑ , 2017-09-01: Polysaccharides from macroalgae: Recent advances, innovative technologies and challenges in extraction and purification. Food Research International, Vol. 99, 1011–1020. doi: https://doi.org/10.1016/j.foodres.2016.11.016

- ↑ , 2013-09-01: Effect of ultrasound frequency on antioxidant activity, total phenolic and anthocyanin content of red raspberry puree. Ultrasonics Sonochemistry, Vol. 20, (5), 1316–1323. doi: https://doi.org/10.1016/j.ultsonch.2013.01.020

- ↑ , 2020-05-01: Study on ultrasound-assisted oxidative desulfurization for crude oil. Ultrasonics Sonochemistry, Vol. 63, 104946. doi: https://doi.org/10.1016/j.ultsonch.2019.104946